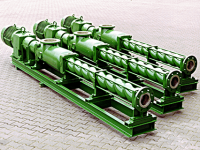

Allweiler’s Progressive Cavity (PC) range of pumps is used to pump or meter thin to highly viscous liquids, pasty, neutral or aggressive, pure or abrasive liquids, gaseous liquids or liquids that tend to foam. These quality engineered pumps are capable of handling liquids with substantial amounts of solid or fibrous materials suspended within the fluid. They are commonly used in waste water and clarification plants, the chemical, paper and cellulose, soap and grease, paint and coatings, food and beverage, plastics, and ceramics industries as well as in agriculture and in sugar processing, among others.

The AE series is available in two variants, the AE1E and the AE1N. The N range has the larger, and stronger joint construction. It can delivery higher pressures, but due to the larger joints is only capable of delivering lower flow rates (see performance specs on the specification tab and via the attached PDF’s). The same is true for the AED and AEDB range.

- Available in block mount, or long coupled.

- Many seal variants available to suit medium being pumped.

- Range of stator and joint sleeve materials available to suit a broad range of applications

Flanges available as DIN or ANSI compliant

Performance Specification

| AE1E | AE1N | AED1E | AED1N |

| Capacity (L/min) | 7,500 | 4,850 | 12,000 | 7,500 |

| Delivery Pressure (Bar) | 6 | 12 | 8 | 16 (2 stage) |

| Discharge Pressure (Bar) | 16 | 16 | 16 | 16 |

| Viscosity Range (mm2/sec) | 30,000 | 30,000 | 225,000 | 225,000 |

| Temperature (Degrees Celsius) | 150 | 150 | 150 | 150 |

| Admissible Solids (% by Volume) | 60 | 60 | 60 | 60 |

| Solids (size and length) | Varies Depending on Unit Size | Varies Depending on Unit Size | Varies Depending on Unit Size | Varies Depending on Unit Size |

Note: “B” as in AEB represents the close coupled, or block style construction. The straight AE is the long coupled design.

- Available in DIN or ANSI flanges.

- Seal Type – see data sheets (many variants available).

- The AE series have a 1/2 geometry and covers the majority of applications, while the AED pumps have a 2/3 geometry.